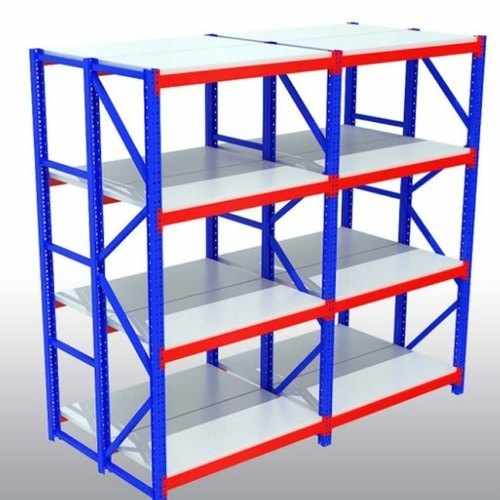

In today’s fast-paced industrial world, Heavy Duty Rack Manufacturers play a critical role in supporting storage infrastructure. Whether it’s a warehouse, retail storage area, or manufacturing unit, durable and safe racking systems are essential. But how do manufacturers ensure that these racks are strong, long-lasting, and safe for daily use?

Let’s break it down in simple terms for everyone to understand, from business owners to students and general readers.

Why Safety and Durability Matter in Racking Systems

Storage racks hold heavy materials — sometimes thousands of kilos. If these systems fail, the results can be dangerous, damaging goods, injuring workers, and disrupting operations. That’s why safety and durability are not optional — they are a must.

Heavy Duty Rack Manufacturers focus on these aspects from the very beginning of production, using design, quality control, and engineering to deliver reliable products.

What Makes a Rack “Heavy Duty”?

Before we get into the safety part, it’s important to understand what makes a rack “heavy duty” in the first place.

Strong Raw Materials

Most racks are made from high-quality steel or reinforced metal. These materials are strong, resistant to corrosion, and capable of handling heavy weights over long periods.

Load-Bearing Capacity

Heavy duty racks are designed to hold large, bulky, or heavy items without bending or breaking. Manufacturers test each rack’s load-bearing limits before final approval.

Steps Heavy Duty Rack Manufacturers Take to Ensure Safety

Smart Engineering & Design

It all begins with intelligent design. Manufacturers work with engineers to:

Calculate load distribution

Prevent imbalance and tipping

Optimize space without compromising safety

Every curve, joint, and support is designed with the user’s safety in mind.

Material Testing & Quality Checks

Reputed Heavy Duty Rack Manufacturers do not compromise on raw materials. They perform:

Stress tests on materials to ensure they can take heavy loads

Welding checks to make sure joints are firm and stable

Powder coating or galvanization to avoid rust and increase lifespan

Compliance with Safety Standards

Good manufacturers always follow international safety guidelines such as:

ISO standards

OSHA requirements

BIS certification (in India)

This ensures the product is both safe to use and legally compliant.

Seismic and Impact Resistance

In regions prone to earthquakes or heavy movement, racks are built with seismic protection features. Even in normal environments, racks are tested for accidental impact, such as forklift hits.

Durability Factors You Should Know

Safety is just one side of the coin; durability is the long-term promise.

Anti-Corrosion Protection

Steel racks can corrode over time. To avoid this, Heavy Duty Rack Manufacturers apply:

Powder coatings

Zinc galvanization

Rust-resistant paints

This prevents wear and tear and makes racks suitable for cold storage, chemical zones, or outdoor units.

Modular Design for Maintenance

Manufacturers offer modular parts that are easy to replace. If one section gets damaged, you don’t have to replace the entire rack — just swap the damaged section. This adds to the system’s overall lifespan.

Load Labels and User Guidance

Many racks come with clear labels showing maximum load capacity and safety tips. This helps users avoid overloading, which is a major cause of rack failures.

Installation and Training Support

Safety doesn’t end at manufacturing. Heavy Duty Rack Manufacturers often provide:

Professional Installation

Improper installation can cause even the best-designed racks to fail. Manufacturers either send trained teams or provide step-by-step installation manuals.

User Training

Basic training is sometimes offered for warehouse staff, covering:

Safe loading practices

Height restrictions

Inspection routines

This ensures the racks are used correctly and stay safe for years.

Regular Inspections and After-Sales Support

Good manufacturers offer after-sales support to extend safety and durability.

Annual Maintenance Contracts (AMCs)

With AMCs, racks are inspected regularly for:

Rust

Structural damage

Loose bolts

Load stress

Timely repairs prevent small issues from turning into major problems.

Easy Spare Part Availability

Spare parts are made easily available to maintain functionality without downtime.

Conclusion: Choosing the Right Manufacturer Makes All the Difference

When safety and durability are your top priorities, choosing the right manufacturer becomes a critical decision. Reliable Heavy Duty Rack Manufacturers follow strict quality protocols, safety standards, and offer long-term durability features that protect your goods and people.

One such name in the industry is Shree Mahalaxmi Steel Industries, known for delivering high-quality, safe, and long-lasting heavy duty racking systems across industries. Investing in the right racks today means saving lives, money, and effort tomorrow.

Write a comment ...